Skip to main content

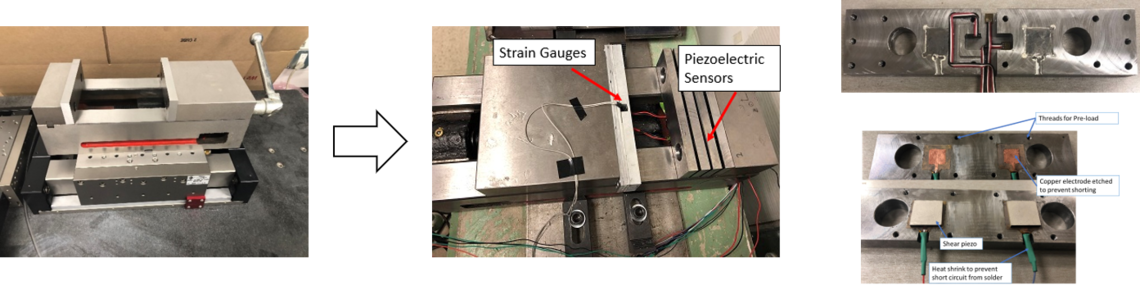

Cutting force measurement (funded by KIMM)

- Motivation: Need to measure clamping force and cutting force

- Challenge: Embedding sensors, Decoupling Force, dynamic compensation

- Goal: Develop a smart-vise device

- Collaborating with Dr. Park

- Motivation: Need to automate a certain manufacturing process

- Challenge: A specified system mechanism and vision technology are needed

- Goal: Develop an automated manufacturing process platform

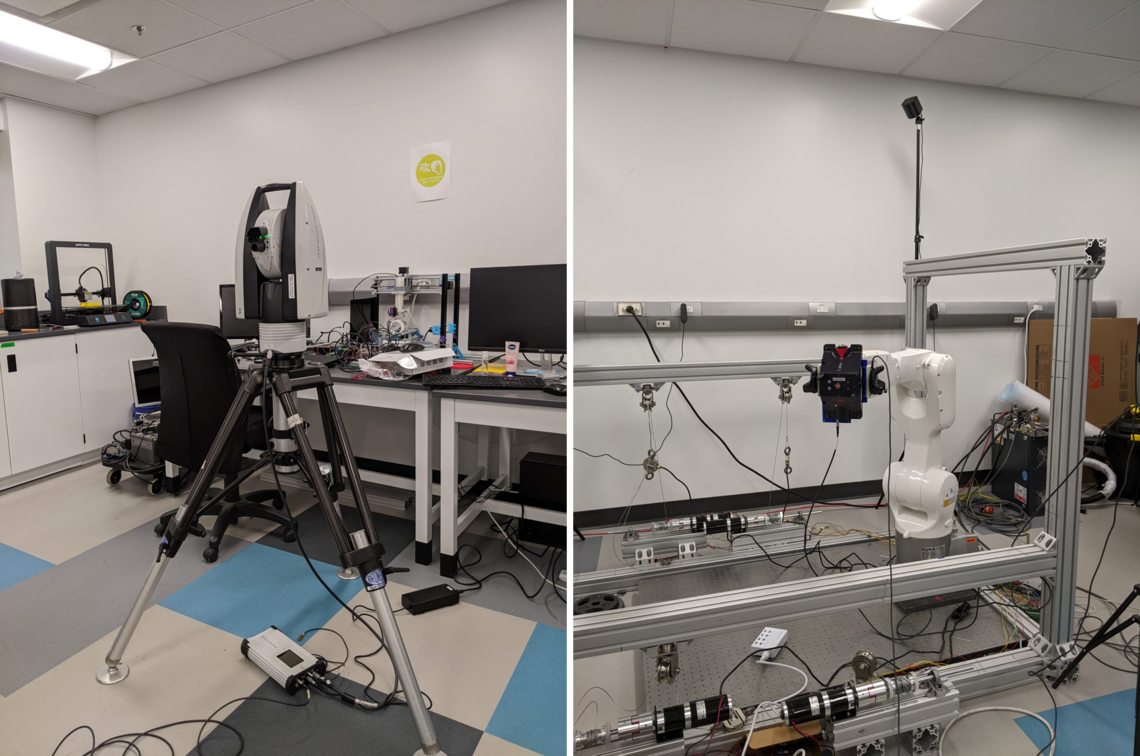

Low-cost and high-accuracy position tracking system (funded by URGC)

- Motivation: Need a high-accurate and low-cost tracking device

- Challenge: signal drift, tilted local coordinates, and low static/dynamic accuracy

- Goal: Develop a tracking system based on VR tracker

- Challenge: robotic 3D printing system needs to create and automatically update a tool path

- Novelty: novel bioprinting, vision-based tool path generation

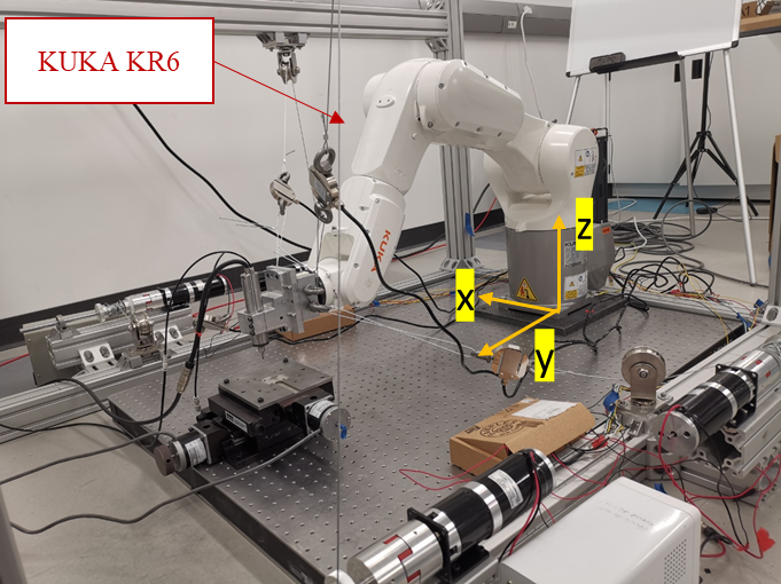

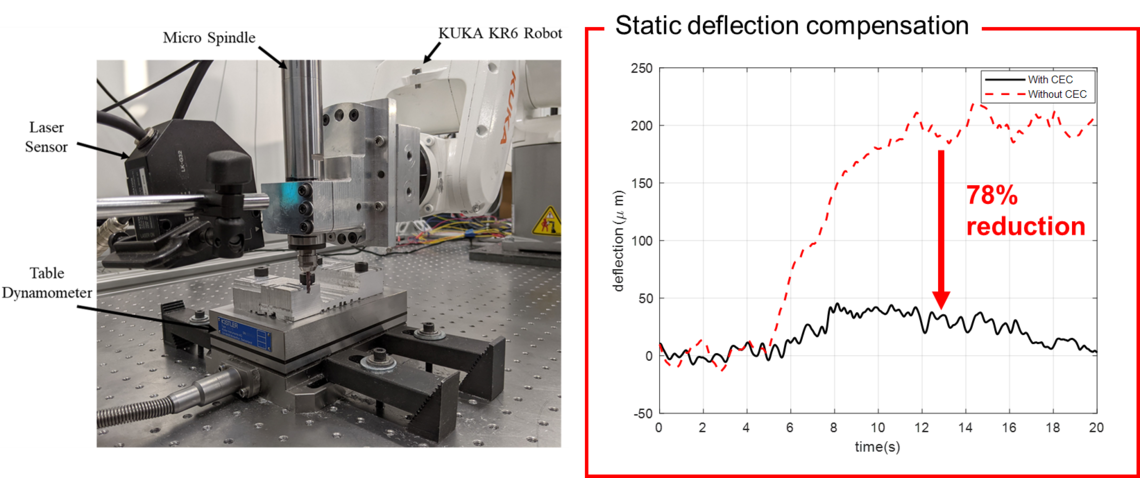

- Challenge : 50 times lower structural stiffness than that of CNC machine tools

- Novelty: Installing an optimal configuration of cables at the robot/ Controlling the cable to track the robot’s movement

- Outcome: 5~10 times stiffness improvement , Milling steel using the robot

- Challenge: Robot is easily deflected while machining

- Novelty: Cutting force estimation using nonlinear disturbance observer & compliance error compensation

- Outcome: 75% reduction of the static deflection