Microactivity Effi MAE20200

The Microactivity Effi is a fixed-bed microreactor for use in catalytic activity measurements, including kinetic studies and reaction performance evaluations. It boasts full automation through intelligent software and thus, enables long-term studies to be conducted safely and remotely if necessary. Below are listed some of its properties:

- 3x high precision Mass flow controllers with digital communications.

- Heated liquid feed line and reservoir (up to 80°C), enabling introduction of more viscous feedstocks. Positive pressure applied to liquid reservoir to assist pump (pump has a maximum operating pressure of 400 bar).

- A SS316 tubular reactor, 9.1 mm. ID with easy loading of up to 3.3 cc. catalyst. Thermocouple placed directly in catalyst bed.

- Maximum working pressure up to 100 ± 0.1 bar at 650°C.

- Hot box to ensure vaporization of feedstocks before entering reactor.

- High pressure Liquid/Gas separator (L1) with capacitive level sensor and very low dead volume (less than 1 cc.), allowing real time results without accumulation.

- Separator calibration depending on nature of liquid product.

- User-defined alarm system.

Fixed bed micro-reactor system

This system has three gas lines individually controlled by a calibrated mass flow controller (5-50 mL/min) which can be used to deliver gas feedstock. Liquid feedstock like crude oil stored in a heated tank can also be sent into the system through heat traced pipelines in a controlled matter (0-10 mL/min). Catalyst powders with volume up to 1 mL can be held inside a vertically oriented reactor with 20 mL capacity heated by an electric furnace up to 600 oC and operated under fixed bed mode. Upon reaction, the formed products pass through a condenser for gas/liquid separation. Two high-pressure separators connected in series are engaged for liquid product collection. The separated gas products are then sent into a gas storage tank for gas sample collection followed by a gas trapping bottle filled with alkaline solution for toxic species removal before being discharged into atmosphere. The whole system can be operated under high pressure up to 10 MPa controlled by a back pressure regulator. The operation of the system is fully automated and controlled and monitored by a computer installed with a professional software.

High pressure, high temperature, magnetic stirred Parr reactor

- 300 mL capacity

- Precise measurement of temperature and pressure

- 16 in/lb magnetic stirrer

- Rated for use at up to 2000 psi at 500 C

- 1/8 hp Variable speed motor

- 800 watts heater assembly

- 4848 temperature controller with possible PC communication

- Solenoid valve module to control cooling

- Head to include 0~2000 psi gage, 2000 psi rupture disc with double valve assembly with dip tube, gas release valve, thermocouple and cooling loop

- T316 stainless steel body material

High pressure, high temperature, magnetic stirred Parr reactor

- 300 mL capacity

- Precise measurement of temperature and pressure

- 16 in/lb magnetic stirrer

- Rated for use at up to 2000 psi at 500 degree C

- 1/8 hp Variable speed motor

- 800 watts heater assembly

- 4848 temperature controller with possible PC communication

- Solenoid valve module to control cooling

- Head to include 0~2000 psi gage, 2000 psi rupture disc with double valve assembly with dip tube, gas release valve, thermocouple and cooling loop

- T316 stainless steel body material

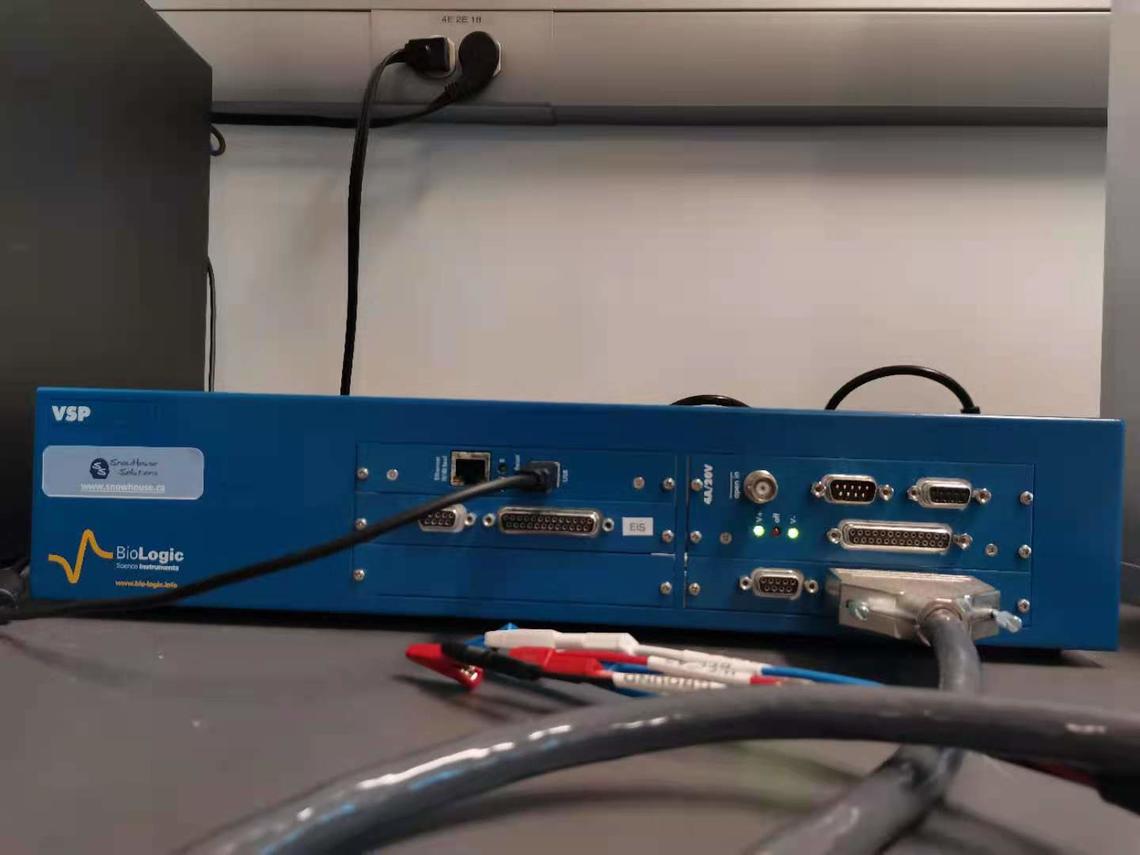

Potentiostat (Biologic VSP)

- 5 channels

- 20 V adjustable reference voltage

- Current ranges: 10 µA-400 mA

- Built-in EIS with frequency range of 10 µHz-1 MHz

- Build-in 4 A booster

Modulated Speed Rotator (PINE research)

- The most popular electrode rotator in the world

- Adjustable range from 50 to 10,000 RPM

- Accuracy within 1% of the reading display

- Silver-carbon brush contacts: red is for the disk, blue is for the ring

- Equipped with rotating disk electrode (RDE), standard platinum counter electrode, Ag/AgCl reference electrode and jacketed glass cell