Facilities / Equipment

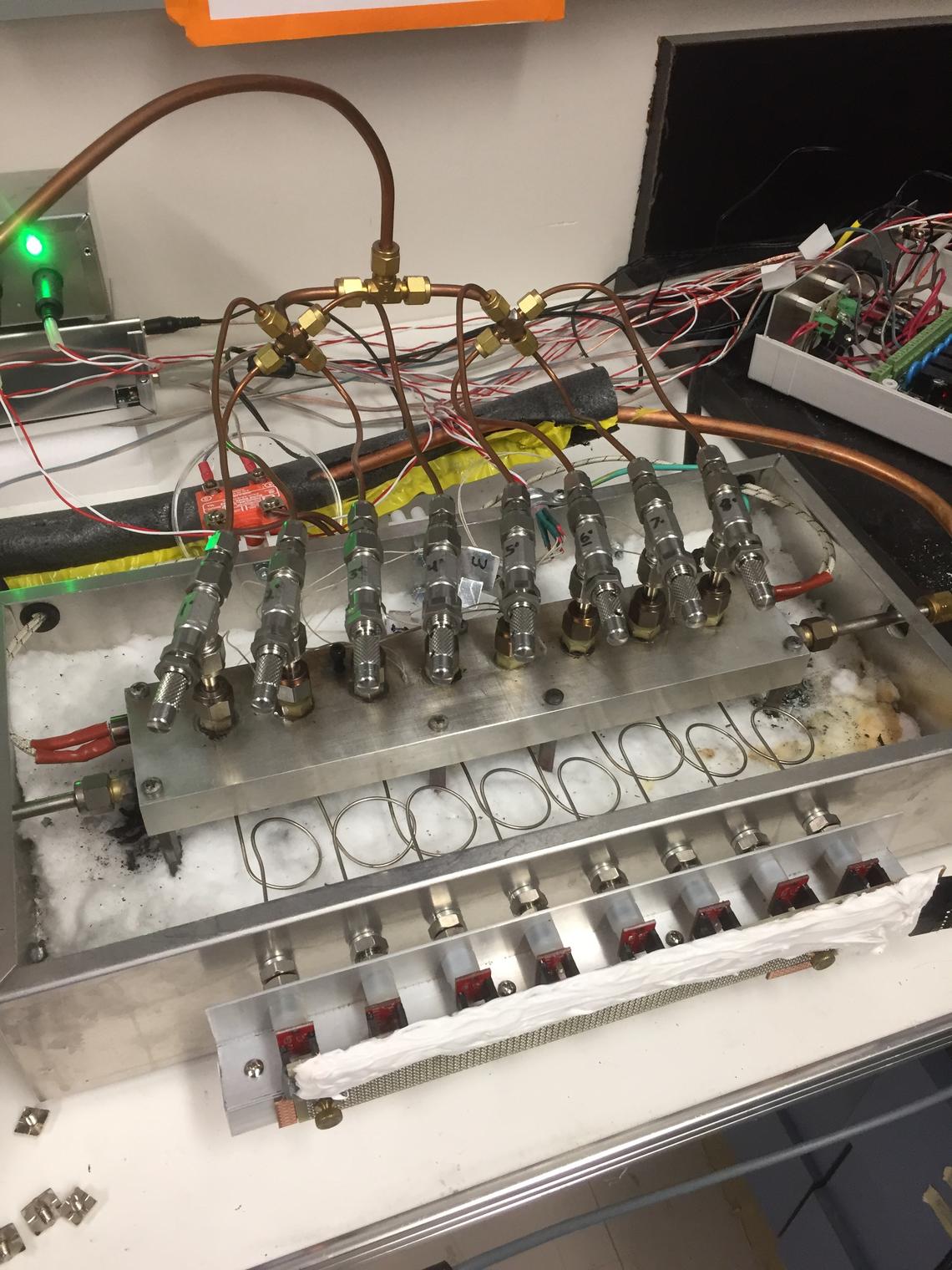

High Pressure Multicomponent Adsorption Apparatus (HPMA)

Dedicated for separation of H2S from sour natural gas, HPMA is a system designed for isotherm measurement and multiple component analysis in a pressure range of 0.1 – 80 bar and a temperature range of -20 – 120 °C. HPMA is composed of a dosing loop and an adsorption vessel with transducers having an accuracy of ±0.0001 bar. The dosing loop and adsorption chamber are sitting in a water/oil bath whose temperature is manipulated within 0.01 °C. Attributed to the small volume of the adsorption chamber and the accurate temperature and pressure measurements, the required amount of adsorbent can be as small as 50 mg. In addition, using the pressure decay (immediately after each dosing) that is recorded with an interval time of milliseconds, the diffusion of the gas phase within the adsorbent can be estimated with known properties of the adsorbents. Moreover, HPMA is equipped with online GC (with TCD and FID detectors) that can analyze the headspace components.

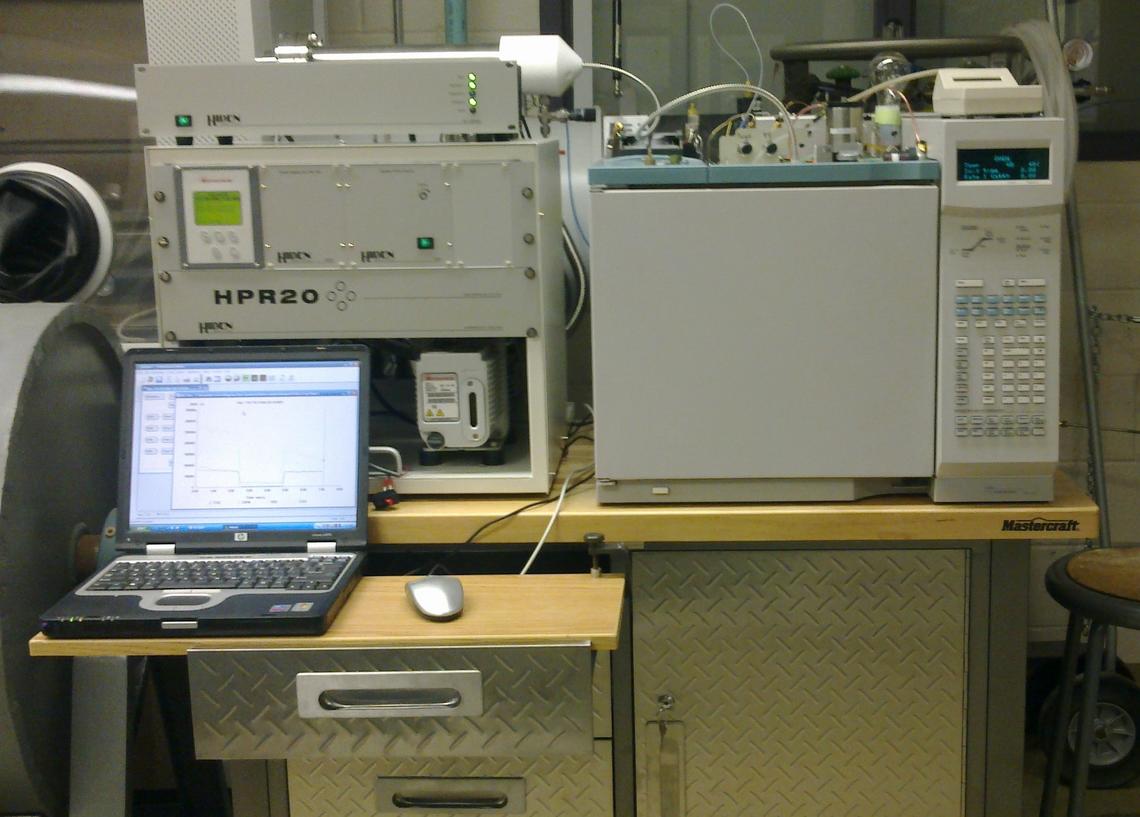

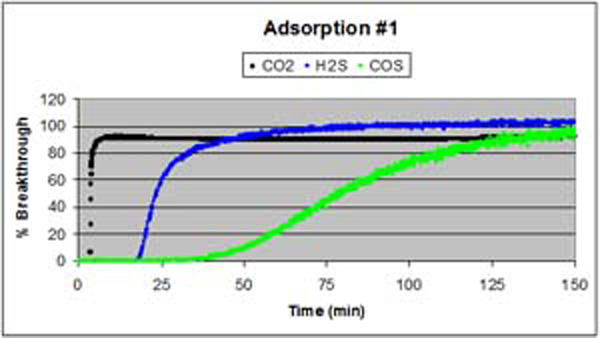

Breakthrough Apparatus

The Breakthrough Apparatus basically consists of a thermostated oven and 2 mass flow controllers, one flow for adsorption gas and one flow for desorption gas. A small amount of the material undergoing testing is contained in a glass cartridge placed within the oven. The Adsorb/Desorb cycles are controlled via software valve switching. The component gases of interest are monitored in real time by a quadrupole mass spectrometer. The amount of information that can be obtained in a single run would take days to obtain utilizing conventional gas chromatography.

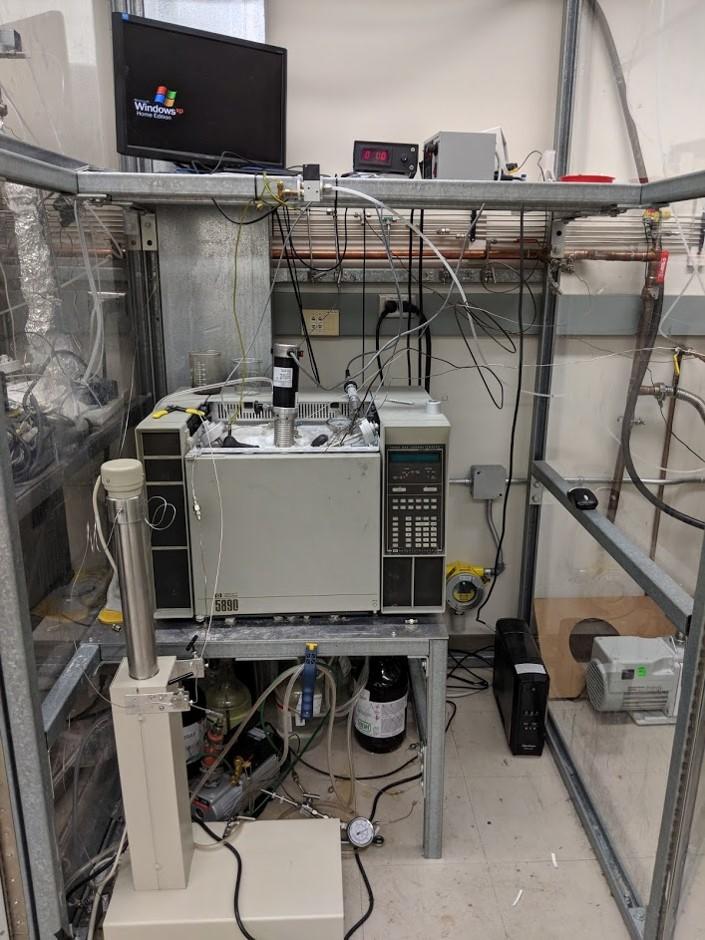

Zero-Length Chromatography (ZLC)

Zero-Length Chromatography (ZLC) is an analytical instrument which allows for the studies of equilibrium and kinetic behavior of adsorption of gases on porous materials. Similar to a conventional GC, the instrument consists of gas inlets, flow-control valve, a ZLC cell where solid sample is loaded, a TCD detector and a data system. The controls of carrier and adsorbate gas flow and sample injection are fully computerized. The ZLC instrument can be further modified for various qualitative and quantitative analyses by interfacing with specific detectors (e.g. SCA) and analyzers (e.g. MS).

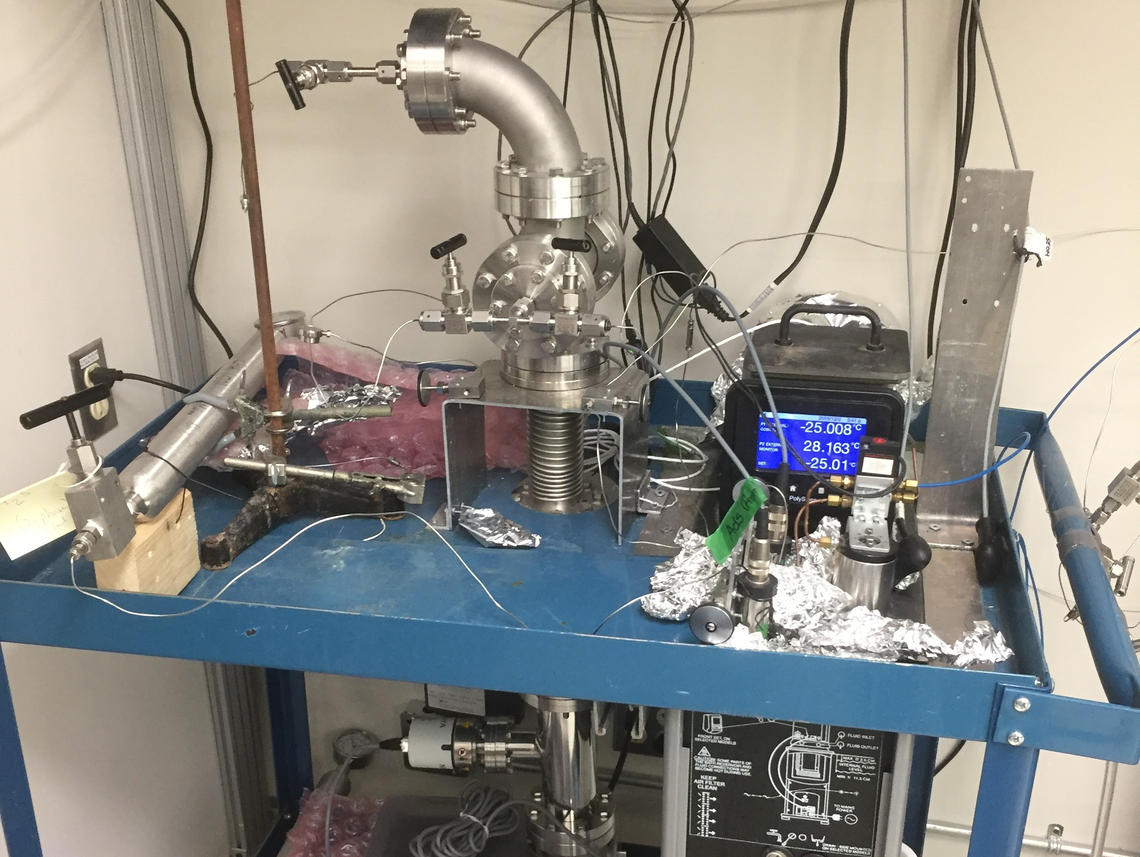

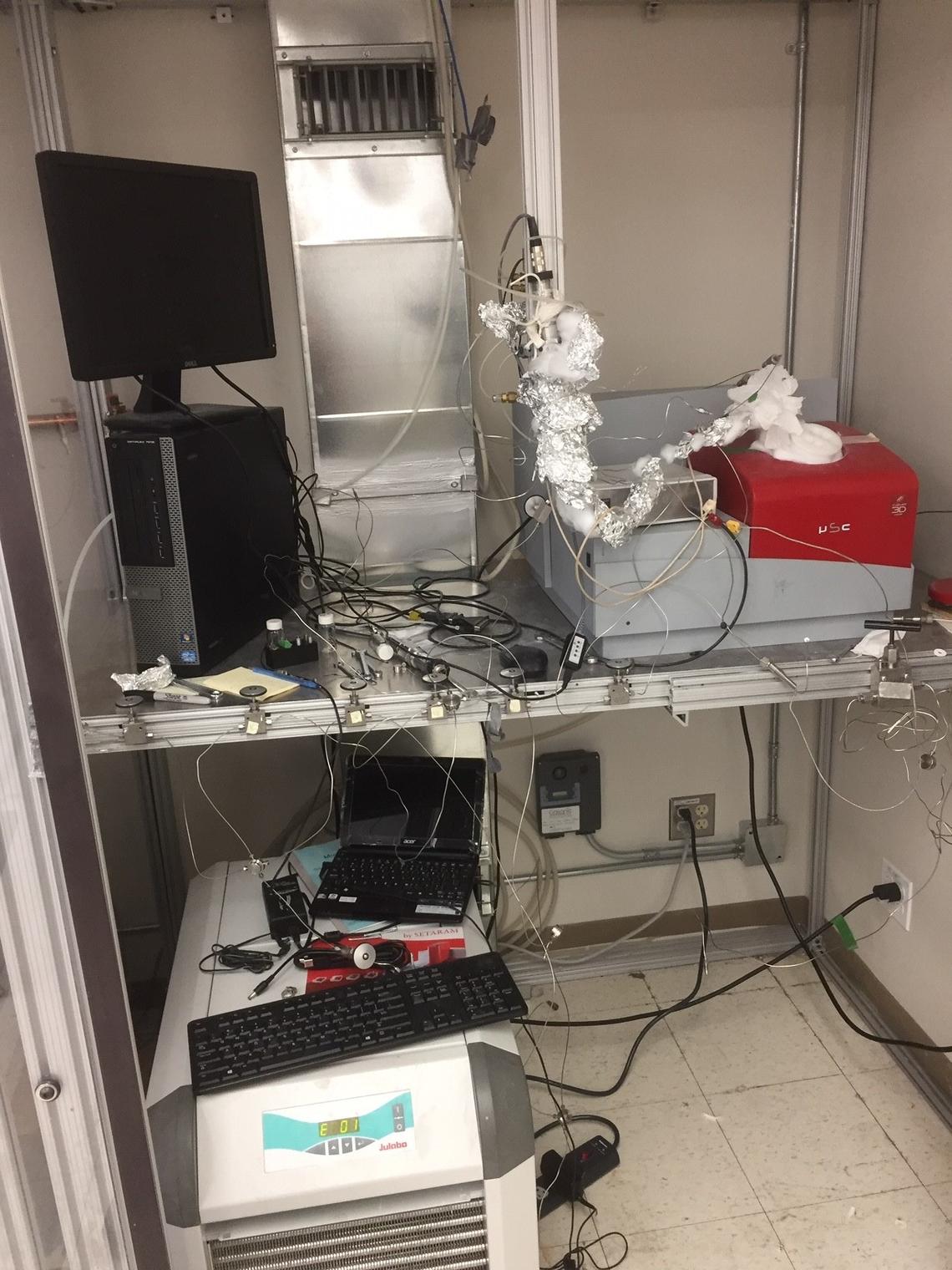

Small Cell Multi Component Adsorption (SCMA)

The SCMA is a second generation HPMA for p= 0.1 to 207 bar and T= -40 to 200oC. This apparatus is designed for isotherm measurement and multi component analysis of high-pressure sour gas fluids.

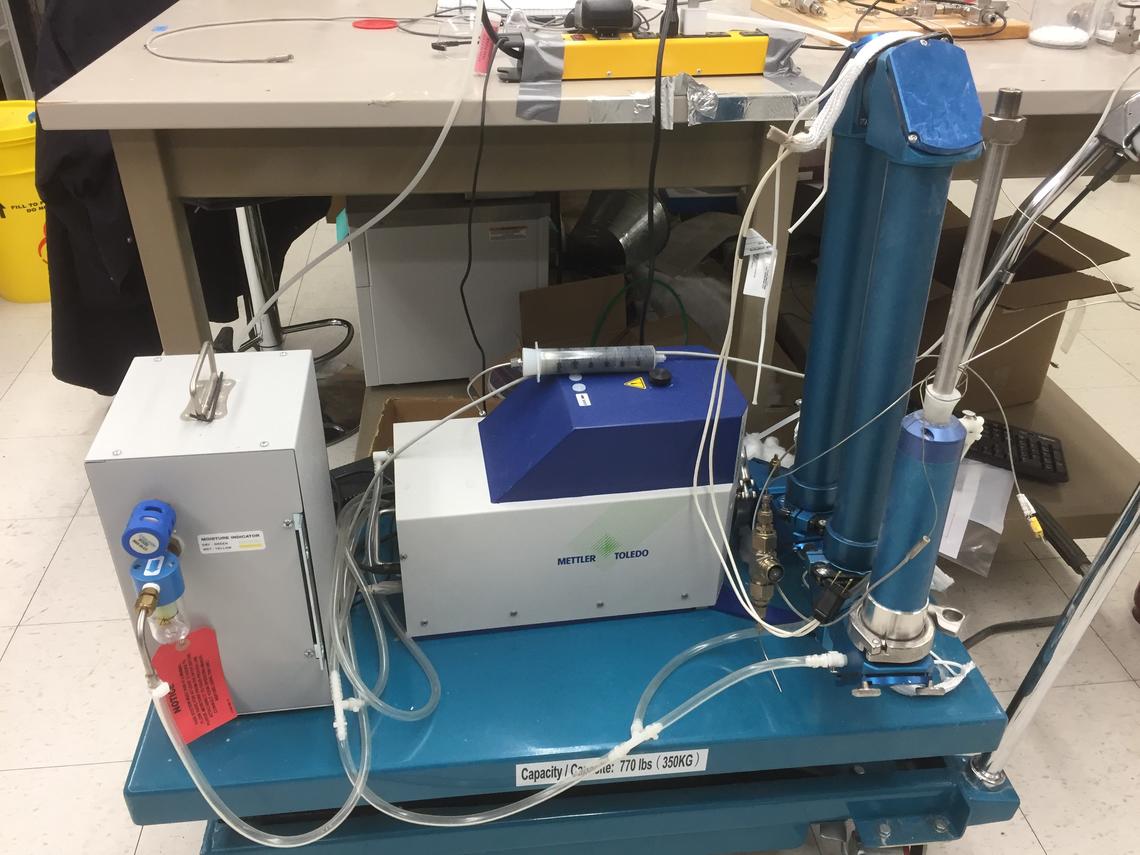

High Pressure In-Situ FTIR Reaction Analysis

The Mettler Toledo ReactIR™ iC10 is an FTIR based in-situ analysis system designed for the study of the microscopic behavior of molecules adsorbed in a microporous adsorbent at p=0 to 100 bar and T= 0 to 300oC.

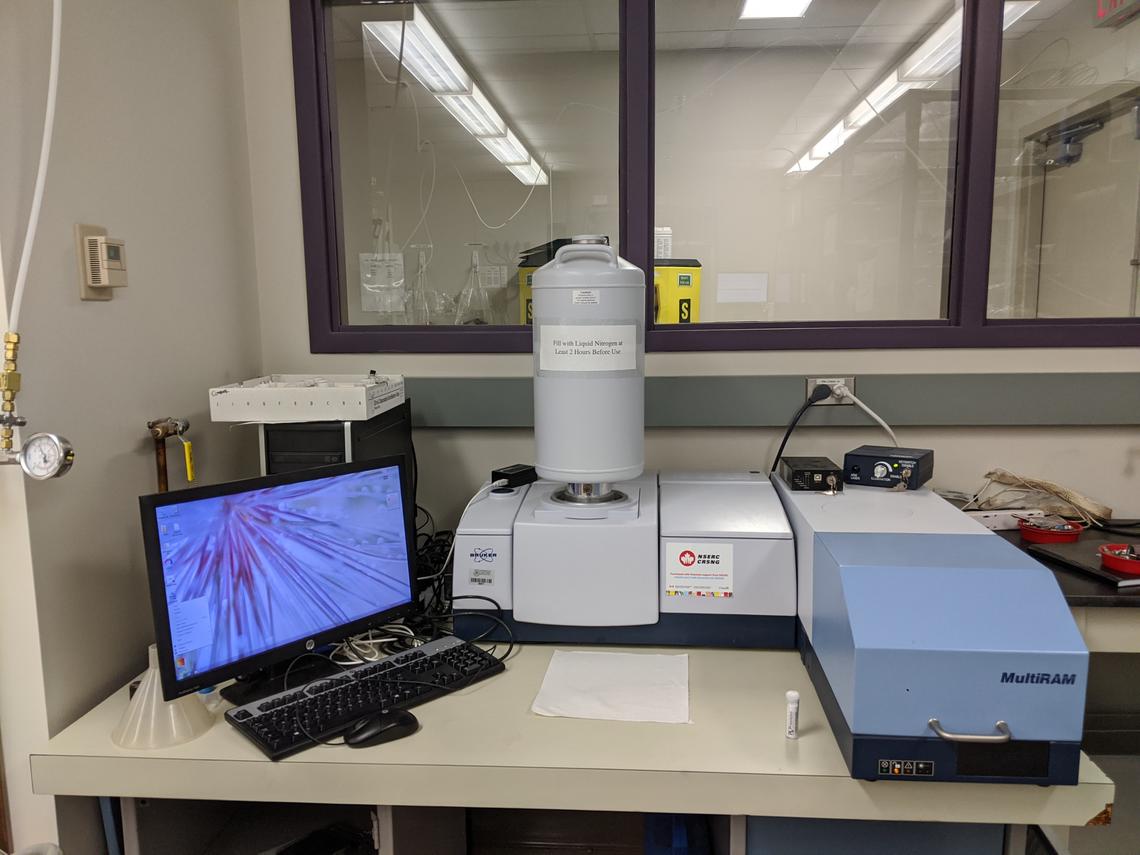

Fourier Transform Raman Spectrometer

Our Bruker MultiRAM FT-Raman spectrometer is being used to study the surface adsorption of sour gas on microporous adsorbents with spectral range of 3600 – 50 cm-1. The standard environmental chamber is constructed from stainless steel materials and a ZnSe widow; it can be operated under vacuum conditions as well as pressures and temperatures up to 500 psi and 800oC, respectively.

Vibrating Tube Densimetry

The in-house built densimeter can be operated up to p= 350 bar and T= 150oC. The small volume, light tube, excellent temperature and pressure control allows for the measurement of high pressure acid gas fluids at applicable conditions.

Small Volume Autoclave

The 25mL stirred autoclave system is designed to study gas clathrate hydrate phase equilibria at p = 1 to 150 bar and T = -40 to 100oC.

High Pressure Differential Scanning Calorimeter

The instrument is capable of performing highly sensitive differential scanning calorimetry measurements for various fluids on wide ranges of temperature under pressures up to 1000 bar.

Thermo-Gravimetric Analysis (TGA) Instrument

Allows for the determination of water adsorption by the change in mass observed in the TGA.

The setup consists of a mass flow/temperature controlled water delivery system that can deliver water from 50 to 8000 ppm directly to the TGA oven.

Rheology of Liquid Elemental Sulfur

The Anton Paar Modular Compact Rheometer 302 equipped with a concentric cylinder pressure cell rated up to p = 1000 bar and T = 300 °C. The addition of a custom-built gravity-fed charging rig allows for the metered flow of liquid sulfur into the pressure cell, while a custom-built head pressure tee allows for the introduction of partial pressures of gaseous impurities. The impurities, such as H2S, are then quantified before and after rheometric measurement utilizing a Thermo Scientific Nicolet 380 FT-IR spectrometer in order to determine their impact on the rheology of liquid sulfur.

Surface Characterization Analyzer

The Micromeritics 3Flex surface characterization analyzer is capable of performing physisorption and chemisorption analyses with high accuracy and resolution.

High Pressure Sulfur Recovery

High pressure oxidation of H2S within CO2 for low-level sulfur recovery.

Rapid Adsorption Cycling Apparatus

This rapid cycling thermal swing adsorption apparatus is used for studying the long term deactivation of solid adsorbents.