Processing Tools

The equipment showcased here are located in our processing lab.

Contact Details

Location: Suncor Building, Department of Mechanical and Manufacturing Engineering.

Room: MEB 516

Phone number: (403) 210-6557, (403) 220-4704

Union Process SD-1 Laboratory Attritor

This Laboratory Attritor is an easy and precise scale-up to production-size equipment used for mechanical alloying. It is a versatile, reliable, rugged lab mill designed to meet virtually all lab grinding and dispersing needs – wet or dry, continuous or batch, in an inert atmosphere.

MNT PBM-04 Planetary Ball Mill

The planetary ball mill PBM-04 is a compact device for mixing, homogenizing, fine grinding, mechanical alloying, and many other applications. It has multiple grinding modes and a LED display for control and monitoring. It constitutes four jars that can process four samples in a single experimental batch (suitable for rapid screening). It has a rotational speed of up to 600rpm. Processed materials are ground by Coriolis forces, an interaction between frictional and impact forces, as a result of the difference in speeds between the balls and grinding jars.

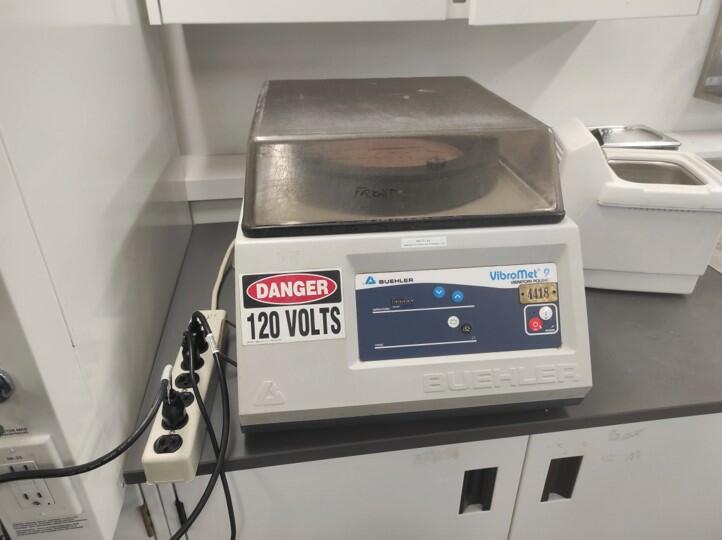

Vibromet Vibratory Polisher

VibroMet 2 Vibratory Polisher is a machine designed to prepare high-quality polished surfaces on a wide variety of materials, including EBSD applications. After mechanical specimen preparation, the Vibratory Polisher removes any minor deformations left on the surface. This helps to ensure a stress-free surface without the need for hazardous electrolytes required by electro-polishers.

Lindberg Furnace

The Lindberg 59344 furnace oven is an efficient and versatile heating device designed for laboratories seeking reliable and precise heat treatment capabilities. This compact and reliable oven utilizes advanced heating technology to achieve precise temperature control and uniform heat distribution throughout its spacious chamber. With a maximum temperature range of 200-1000 degrees Celsius, it offers exceptional thermal performance for processes such as annealing, heat treating, sintering, and drying. The Lindberg 59344 furnace oven features programmable controls, allowing users to set and monitor temperature parameters with ease.

YLJ-15 Compact Hydraulic Pellet Press

This is a compact manual 15T hydraulic press with a built-in hydraulic pump and an auto-return function for quick die removal & sample retrieval. It is well-suited for operation inside a glove box, where having an inert environment is crucial to prevent unwanted sample contamination. Its normal operating pressure force is 7 metric tons,

The maximum operating pressure force is 15 metric tons with > 50 mm H Die (for < 5 minutes pressure holding). It also has a pressure gauge built-in.

Uline Vacuum Sealer

The Vacuum Sealer is used to vacuum bags up to 19 1/2" wide. It has a hands-free foot pedal operation and temperature controls up to 400° F.

Oil-less Compressor/Pump

The AP-550V pump has a maximum airflow of 5.5ṃ3/h and an ultimate vacuum of 700mmHg

VRC High-Pressure Cold Spray Machine

The VRC® Dragonfly™ is a multi-component high-pressure cold spray system for achieving uniform coating with single or mixed metal powders. It is capable of producing metallurgical bonds 2-10 times stronger than regular low-pressure cold spray. The modular components, including a 21kW heater, are quite portable and mobile.

Shared Facilities

Other shared facilities includes Instron Tensile Test Machine, Vickers, and Rockwell Hardness Testing Machines amongst others