Research Activities

Our research focuses on developing high-performance and durable materials and membrane-electrode-assemblies (MEA) for different electrochemical systems, including fuel cells, water electrolyzers, CO2 electrolyzers, and redox flow batteries. We use a combination of electrochemical characterization techniques, in-situ and operando imaging, and multiscale numerical modeling to understand the transport and electrochemical phenomena in the electrochemical cells and optimize the MEA components. (Relevant publications for the images: [1, 2, 3, 4].)

High activity catalyst layers for Proton Exchange Membrane Water Electrolyzers

Optimizing the structure of the catalyst layer is critical to mitigate the performance losses in PEM water electrolyzer and reduce the loading of expensive iridium catalysts. We are developing novel catalysts to improve the electrochemical performance of the cell. By studying the interactions of the polymer, solvents, and catalyst in the ink, we aim to control the structure of the catalyst layer to obtain optimized microstructures, which will minimize the transport losses and result in high catalyst utilization.

Catalyst layer image: Scientific Reports, 2023

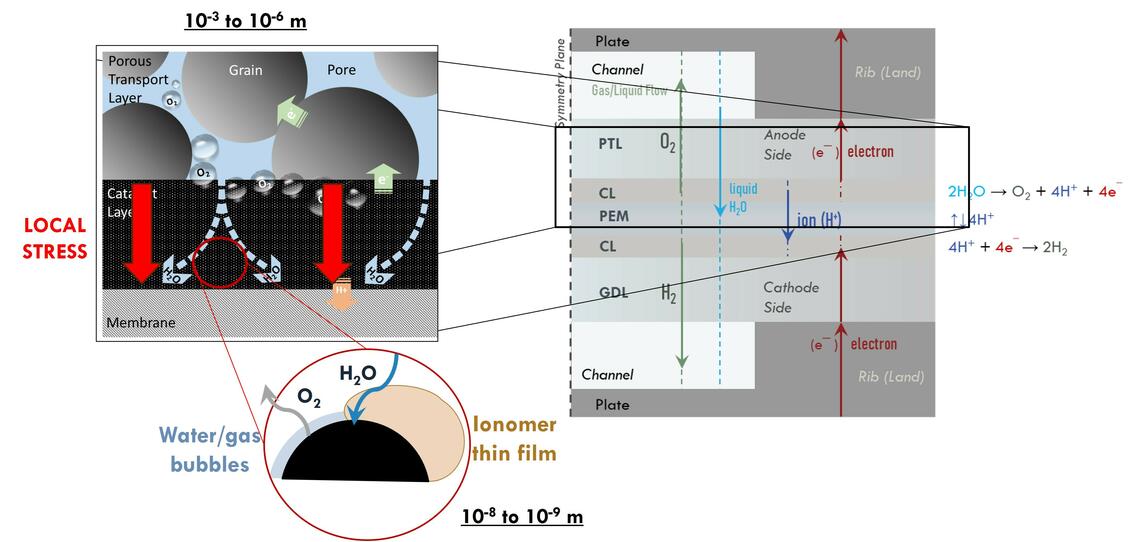

Probing the interfaces at different length-scales

MEA image adapted from the original image by A. Kusoglu (LBNL).

In-situ and operando x-ray computed tomography

High-resolution imaging can provide direct evidence of the local multiphase transport and compression in the porous electrode. This is particularly useful to characterize the microstructure of the porous electrodes and correlate it to the transport and degradation processes. Currently, we are using in-situ and operando XCT to study the multiphase transport in porous transport layers, and the effect of porous transport layer roughness on the membrane durability for water electrolyzers.

Multiscale numerical modeling

Mathematical models are an ideal tool for understanding the physical and electrochemical processes in the membrane-electrode-assembly and therefore, explain experimental observations. Our research group is developing numerical models to simulate the bubble nucleation and growth on the catalyst surface followed by their transport in the nanopores of a catalyst layer. These models are coupled with volume-averaged cell-level models to correlate the bubble transport effects to the overall water electrolyzer performance. These models are being built using the open-source framework, OpenFCST.

Integration of Water Electrolyzers into Microgrids

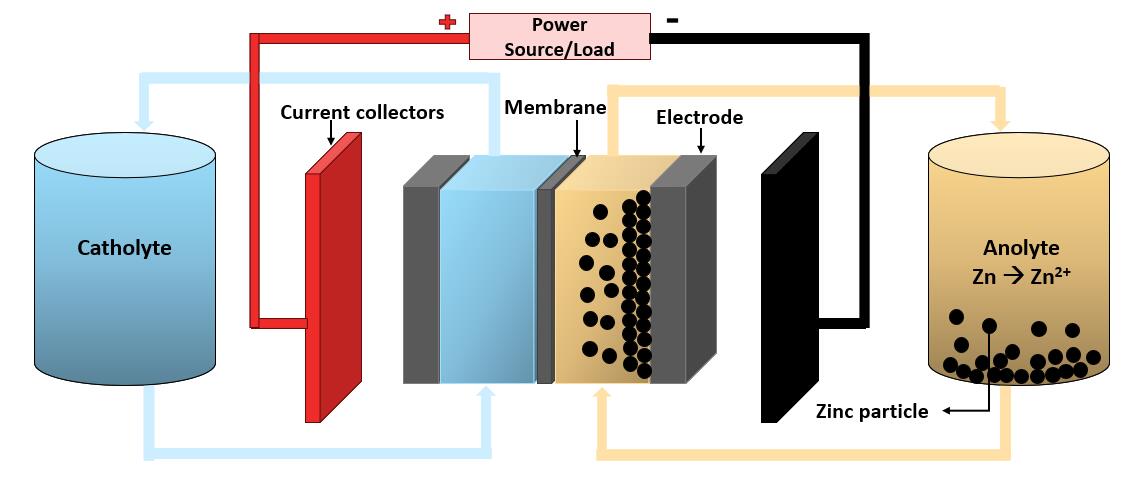

Multiphase Redox Flow Batteries

In collaboration with Dr. Ted Roberts, we are focusing on innovative strategies that leverage zinc dendrites effectively beyond traditional suppression methods to improve the performance and durability of zinc redox flow batteries. Leveraging the expertise of the LEEDR group in operando x-ray computed tomography, we are visualizing the zinc dendrite formation in real-time and using this information to optimize the electrode structure, properties, and flow conditions.