Skip to main content

- Hardness measurements with simultaneous depth and force measurement

- Scratch testing

- Imaging capability

- Dynamic stiffness measurements

- Automated indentation measurements for spatial distribution of hardness, elastic modulus, or dynamic stiffness over larger surfaces

- Variable temperature (both heating and cooling) measurements

- Contact mode, frequency modulation, Kelvin probe, amplitude modulation modes all possible

- pressures down to 10-11 Torr possible

- atomic and lattice resolution

- Home-built reciprocating tribometer

- Friction measurement under electrochemical controlled environment

- Normal force ranges from 1-50 N

- Pin-on-disc future capability possible

- Upright optical microscope

- Fluorescent imaging capabilities

- Photo-stitching

- Fully automated stage

- Acquisition of scaled images

- 1" tube furnace capable of heating samples to 1200oC

- Heating under low-vacuum conditions (~mTorr)

- Three gas feedthrough with flow control

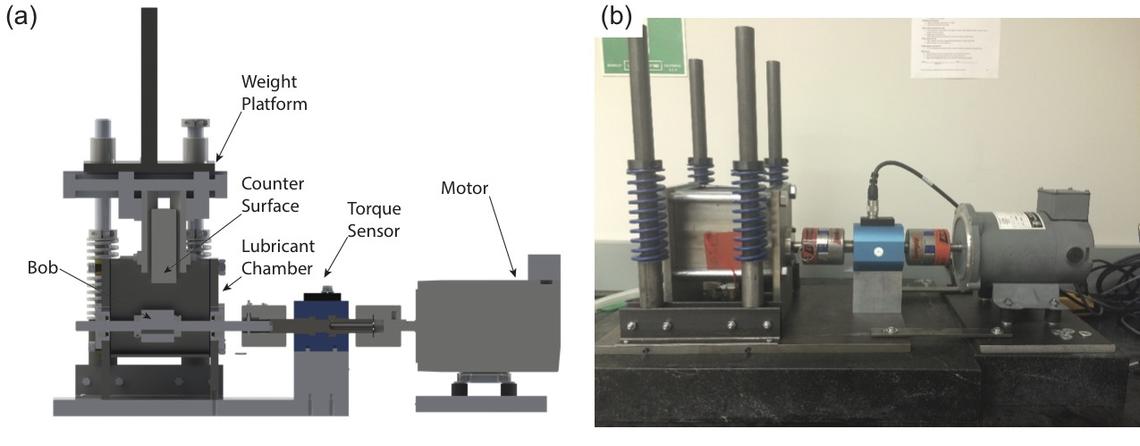

- Home built tribometer

- Rotational capability from 0 RPM to 240 RPM

- Measurement of friction between a rock/core sample and steel (or other metal)

- Heating capability

- Controlled lubricant bath during sliding

- Automated grinding and polishing of samples

- Multiple sample throughput

NANS/Nanoscience Program Facility