Dynamic Loading of Pipelines during Integrity Management

The purpose of the project is to improve pipeline safety. While leak detection and spill remediation are important, it is more desirable to prevent incidents in the first place. The project will develop knowledge, technologies and best practices that promote pipeline integrity at the highest level possible. Ensuring the safe and reliable transportation of energy products by pipelines is crucial, irrespective of whether this energy is derived from fossil fuels or from renewable sources.

The research is carried out by a multidisciplinary team in collaboration with a global leader in the pipeline transportation of gas and liquid hydrocarbons. My colaborators are tenured faculty members at the University of Calgary. PhD and MSc students are an essential part of the team.

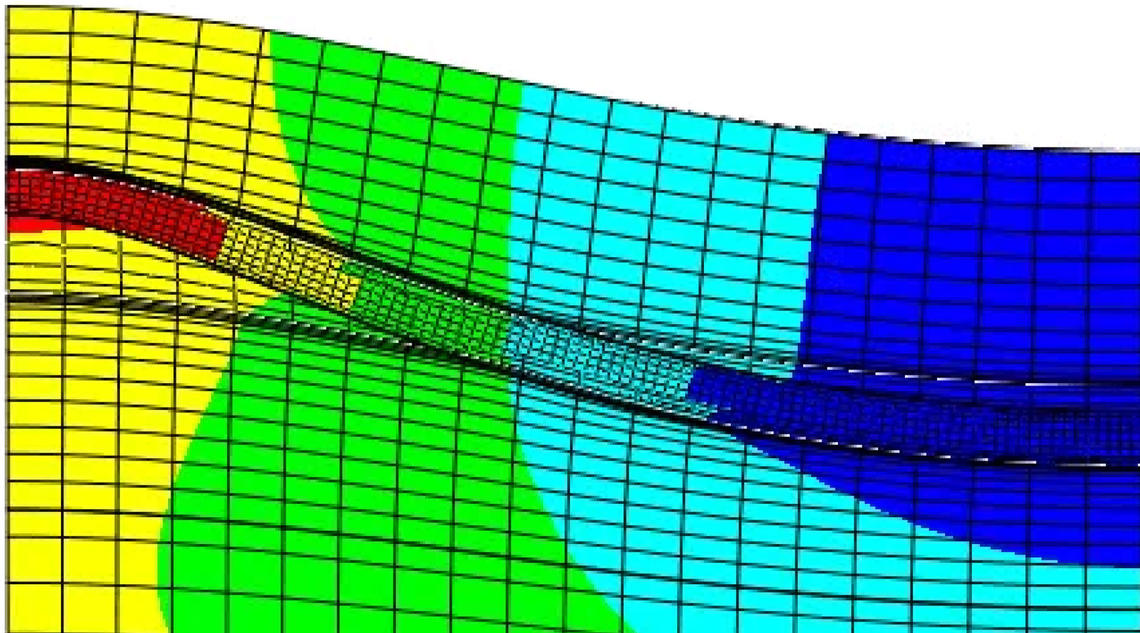

The project assesses the stress regime when an In-Line Inspection tool passes through a pipe as part of an integrity management procedure. This is an unexplored area that will result in a new understanding of the combined effects of stress, fatigue and material loss. In some cases, these effects can be compounded in a pipe that is potentially vulnerable due to weld or corrosion defects.

Using a combination of numerical modeling and subscale experiments, an artificial intelligence model will be developed to predict maximum stress and crack propagation rate for a variety of input conditions, including temperature change, welds, corrosion, and crack propagation. The model will result in a software tool for use by pipeline engineers in real-world situations to improve the robustness integrity management programs.

This study will address unknowns and will create new knowledge about a frequent pipeline integrity procedure, but the research approach will also allow applicability to the effects of surrounding environment such as open pit pipe during pipe excavation procedures, water crossings and muskeg.

We acknowledge the support of the Natural Sciences and Engineering Research Council of Canada (NSERC).

Cette recherche a été financée par le Conseil de recherches en sciences naturelles et en génie du Canada (CRSNG).